-

This thread is to compare battery chemistries in different EVs. I am editing and updating this first post of the thread with complete details about the Soul EV battery. There is also a thread discussing the layout and position of the battery pack - Comparing the Soul EV battery with the Ioniq EV

The Soul EV has a battery by SK Innovation.

It has polymer pouch type cells, lithium nickel manganese cobalt oxide (NMC) cathode, a “special” ceramic separator with improved thermal resistance properties (presumably a wet separator by SK Innovation), high-capacity silicon/graphite (Si-C) anode and gel electrolyte additive materials. Each 40Ah battery cell has energy density of 200 Wh/kg

Press Release

=============

1./ Advanced battery for Kia Soul EV

2./ Kia pushes energy-density frontier with Soul EV battery

U.S. Advanced Battery Consortium Reports

=================================

3./ FY2014_APR_Energy_Storage_R&D (for SK Innovation E400 see printed pages 47-49, on screen pages 95-97)

4./ 2013USDRIVEAccomplishmentsReport (for SK Innovation E400 see printed page 32, on screen page 39)

5./ USABC_Final_Report_June_2014 (for SK Innovation E400 see printed pages E21-E23, on screen pages 145-147)

Lithium Ion Battery Components

6./ SK Innovation to Increase Production Capability of Lithium Battery Separator

-------------------------------------------------------------------------------------------

While looking for reasons why the Volt degrades less than the L eaf I found this info from Charles Whalen: (written in October 2010)

http://gm-volt.com/forum/showthread.php?5243-Volt-thermal-management-system-temperature-band/page2

This thread is to compare battery chemistries in different EVs. I am editing and updating this first post of the thread with complete details about the Soul EV battery. There is also a thread discussing the layout and position of the battery pack - Comparing the Soul EV battery with the Ioniq EV

The Soul EV has a battery by SK Innovation.

It has polymer pouch type cells, lithium nickel manganese cobalt oxide (NMC) cathode, a “special” ceramic separator with improved thermal resistance properties (presumably a wet separator by SK Innovation), high-capacity silicon/graphite (Si-C) anode and gel electrolyte additive materials. Each 40Ah battery cell has energy density of 200 Wh/kg

Press Release

=============

1./ Advanced battery for Kia Soul EV

2./ Kia pushes energy-density frontier with Soul EV battery

U.S. Advanced Battery Consortium Reports

=================================

3./ FY2014_APR_Energy_Storage_R&D (for SK Innovation E400 see printed pages 47-49, on screen pages 95-97)

4./ 2013USDRIVEAccomplishmentsReport (for SK Innovation E400 see printed page 32, on screen page 39)

5./ USABC_Final_Report_June_2014 (for SK Innovation E400 see printed pages E21-E23, on screen pages 145-147)

Lithium Ion Battery Components

6./ SK Innovation to Increase Production Capability of Lithium Battery Separator

-------------------------------------------------------------------------------------------

While looking for reasons why the Volt degrades less than the L eaf I found this info from Charles Whalen: (written in October 2010)

http://gm-volt.com/forum/showthread.php?5243-Volt-thermal-management-system-temperature-band/page2

Charles Whalen said:"... the Volt’s and L eaf’s respective battery packs have nearly identical chemistry, both using a lithium-manganese cathode. They both have the same sensitivity to high temps. Out of all the various lithium cathodic chemistries, lithium-manganese is the most heat sensitive and has the highest and fastest rate of capacity decay and degradation at higher temperatures."

The L eaf’s battery cell is manufactured by NEC, is a pouch type cell with stacked elements, a LiMn2O4 cathode from Nippon Denko, a graphite anode from Hitachi Chemicals, a Celgard PP dry separator, and an EC type LiPF6 electrolyte from Tomiyama.

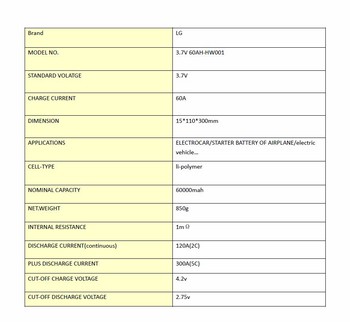

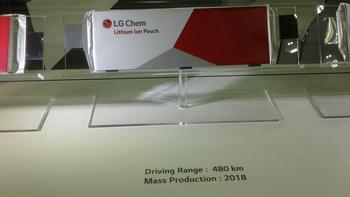

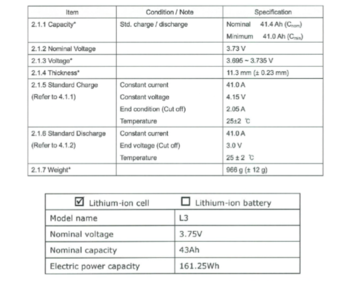

The Volt’s battery cell is manufactured by LG Chem, is a pouch type cell with stacked elements, a LiMn2O4 cathode from Nikki Catalysis, a hard carbon anode (which is more robust and has better/longer calendar life properties than the graphite anode in the L eaf’s battery cell) from Kureha, a Celgard PP dry/SRS separator, and a PC type LiPF6 electrolyte produced in-house by LG Chem.

![300W Car Power Inverter 12V to 110V,PiSFAU DC to AC Car Plug Adapter Outlet with Multi USB[24W USB-C] /USB-Fast Charger(24W) Car Inverter,Car Charger for Laptop Vehicles Road Trip Essentials](https://m.media-amazon.com/images/I/41-KedJShYL._SL500_.jpg)